The vertical suspended centrifugal pumps are designed for pumping fluids on heavy duty process applications.

The FG pump is fully compliant with API-610 11th Edition VS1 and ISO 13709 standards. The pump assembly is partially submerged so the pump does not need priming before operation. The drive unit is located above ground level and is completely accessible.

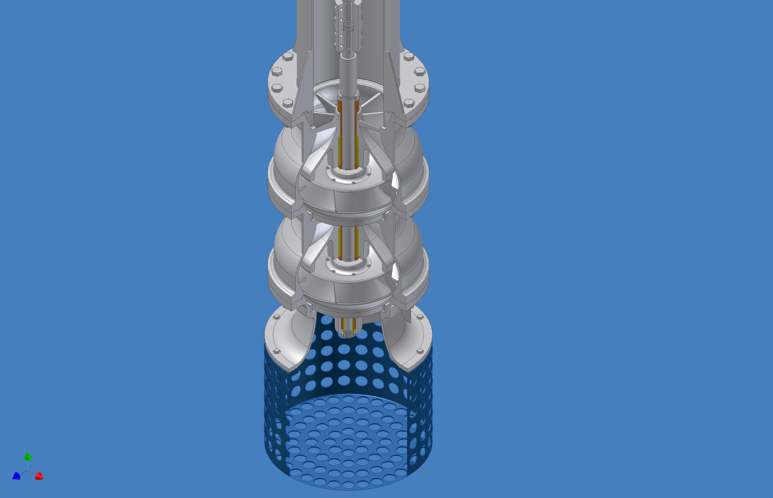

The pump is composed of four components: bowl assembly, column, discharge head and drive unit.

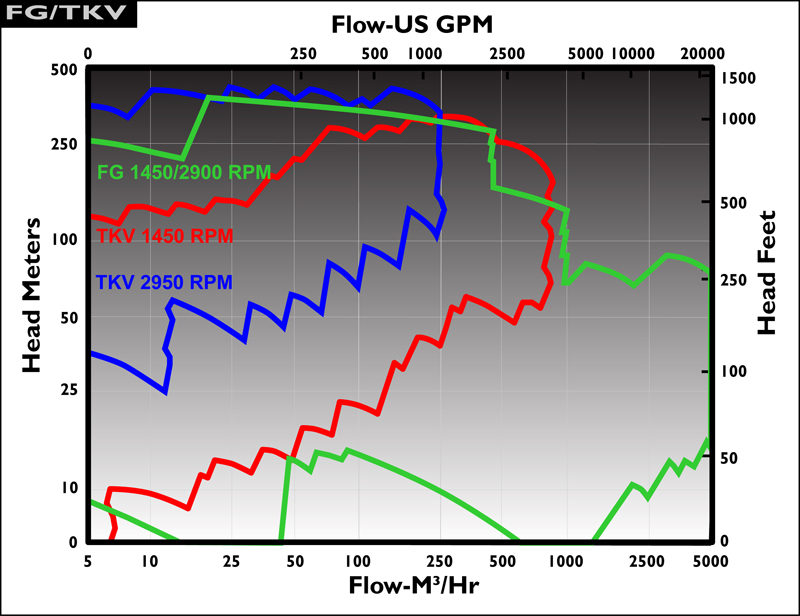

- Flows to 13,209 USgpm (3,000 m³/hr)

- Heads to 1,150 ft (350 m)

- Maximum Working Pressure 189 psi (13 bar)

- Temperature Range -22 to 482°F (-30 to 250°C)

- Pit Depths to 40 ft. (12m)

APPLICATIONS

- Refineries

- Desalination plants

- Process charge

- API Basins

- Condensate extraction

- Tank farms

- Tanks fluid transfer

- Petrochemical plants

- Fertilizers

- Oil fields and terminals

- Off-shore and on-shore installations for petroleum and gas

- Reverse osmosis

- Synfuels

- Paper Mills

- Other intensive heavy duty services

Marelli has more than 50 years of experience in centrifugal pump design, development, manufacturing and service around the world. Vertical suspended centrifugal pumps are a core product family developed under API610/ISO 13709, latest edition standards.

All FG vertical pumps are designed for heavy duty process fluids. The pump assembly is partially submerged, so that the pump does not need priming before operation. The drive unit is located on the surface and is completely accessible. The pump is composed of four components: bowl assembly, column, discharge head and drive unit. The Marelli line of vertical pumps offer a wide range of solutions matched to a wide spectrum of applications.

US 60 Hz

- Heads to 1,150 ft

- Flows to 13,209 USgpm

- Standards API 610, VS1 Type

- Temperature Range -22 to 482°F

- Maximum Working Pressure 189 psi

- Differential Head 656 ft

- Mounting Configuration Vertical Suspended

Metric 50 Hz

- Heads to 350 m

- Flows to 3,000 m3/hr

- Standards ISO 13709

- Temperature Range -30 to 250°C

- Maximum Working Pressure 13 bar

- Differential Head 200 m

- Mounting Configuration Vertical Suspended

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||